Metallic Materials and Processes

We support manufacturers in the development and qualification of materials and processes for the production of critical structures and systems in aircraft, satellites, launchers, and turbomachinery. Our range of expertise includes specialists in physical metallurgy, process simulation, thermomechanical modeling, special processes, and physico-chemical characterization.

Our research focuses primarily on eco-design, resource efficiency, and the durability of metallic materials, structures, and systems.

Central to our activities is the development of tailored materials with specific properties, such as architectured materials and functionally graded materials. We also investigate the extended use of alloys derived from recycling pathways as well as the implementation of repair processes for high value-added components.

Challenges

Developing new manufacturing technologies

- Development of innovative materials and processes

- Development of hybrid manufacturing technologies

- Development of multifunctionality in materials and structures

Optimizing processes and the production chain

- Reducing material costs

- Reducing manufacturing, repair, and maintenance costs

- Reducing development and qualification cycles

Control of material and structural behavior

- Mastering processes (reliability and robustness)

- Mastering the lifetime (initial and residual) of structures

- Mastering the long-term evolution of material properties

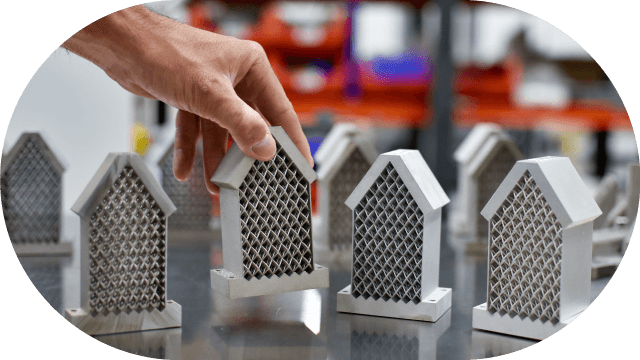

Metal Additive Manufacturing

Additive Manufacturing Machines – Powder and Wire DED:

- Customizing and optimizing the fabrication parameter set for new alloys/powders

- Studies aimed at the eco-design of parts/systems

- Production of aerospace components (proof of concept)

- Repair of components

- Design and production of architectured-material parts

- Evaluation of recycled powders and wires in manufacturing processes

- Fabrication of parts with property gradients

- Generation of near-net-shape preforms for hot forming processes

Hot forming processes

-

Development and fine-tuning of forging and stamping sequences for alloys under development (for aero-structures, engine components, etc.) using limited material volumes compared to standard production tools

-

Hot forming and stamping of raw materials from alternative sources to current standards (PAM billets, preforms from additive manufacturing, preforms from hybrid processes)

-

Development of predictive hot behavior modeling of alloys (rheology, phase transformations, recrystallization, etc.) to enhance process robustness and enable reduction of…

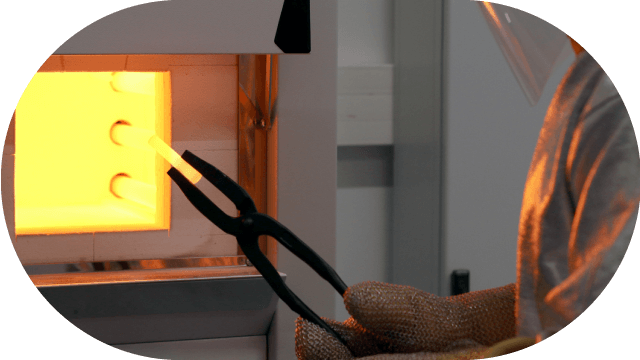

Heat treatment

-

Development of new heat and thermomechanical treatment sequences

-

Development of post-treatments to achieve “on-demand microstructures,” enabling specific macroscopic material properties (mechanical strength, etc.)

-

Metallurgical studies of alloys

-

Characterization of sintering in additive manufacturing powders

-

Study of the influence of thermal aging on material properties

Thermal characterization of alloys

-

Development of new heat and thermomechanical treatment sequences

-

Development of post-treatments to achieve “on-demand microstructures,” enabling specific macroscopic material properties (e.g., mechanical strength)

-

Metallurgical studies of alloys

-

Characterization of sintering in additive manufacturing powders

-

Investigation of the influence of thermal aging on material properties

X-ray tomography

-

3D inspection and analysis of component integrity/material state

-

Quality control of assemblies, porosity evaluation, crack detection, CAD-to-part comparisons

-

In‑operando thermomechanical testing on specimens: tensile and compressive tests from room temperature up to 900 °C

Material characterization

- Sample preparation

- Metallographic analysis (optical and SEM)

- 3D surface analysis and profilometry

- Microhardness characterization