Our testing centers, mainly located in Toulouse and Bordeaux, offer a unique combination of experimental and digital resources covering our four technological focus areas.

Whether it’s exploring new materials within a circular economy approach, developing more resource-efficient AI, optimizing and validating high-performance technological solutions, or accelerating the integration of electric technologies for mobility, our testing centers serve as strategic enablers.

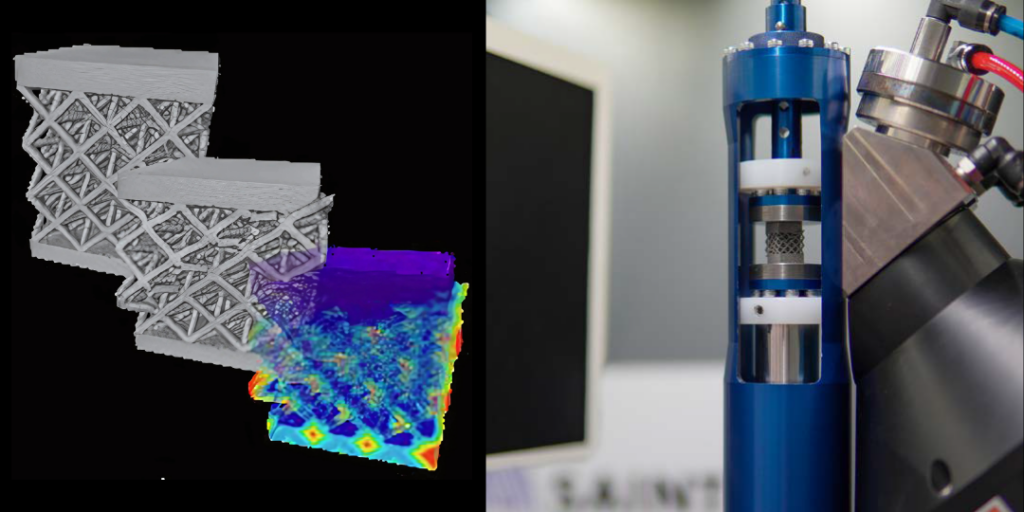

Acquisition of a thermomechanical testing cell integrated with an X-ray microtomograph

The platform service has acquired an in-situ thermomechanical testing system (+/-8kN, testing at room temperature and up to 900°C) designed to integrate directly into the microtomograph.

This versatile device, capable of operating on different types of materials, is a key tool for dynamically establishing the link between 3D microstructure and material damage mechanisms under stress.

Successful industrial transfer of our automated laser process

After optimizing the in-chamber laser treatment process, defining its boundaries, and proving its robustness (defocusing impact, incidence, fluence, contaminants, etc.), we developed inline monitoring and correction tools. Processing complex parts with our robot has validated the reliability of the process. These patented technological building blocks are now being used on the production line of one of our industrial partners.

Laser surface preparation robot with NDT modules

A new MLI tool for timestamping and lifetime measurement of electrical samples

With its new timestamping bench generating a 3kV MLI signal, IRT Saint Exupéry now has a system capable of quantifying the lifetime of five representative electrical equipment samples simultaneously. The principle is based on detecting and timestamping the dielectric breakdown of each sample.