Three years after the launch of the initial SiCRET project, SiCRET+, a project which began in October 2023, is extending the scope of its study to include silicon carbide (SiC) power modules. The aim is to understand the ageing of power modules in normal and degraded operation, and in harsh environments (temperature, humidity, radiation), in[…]

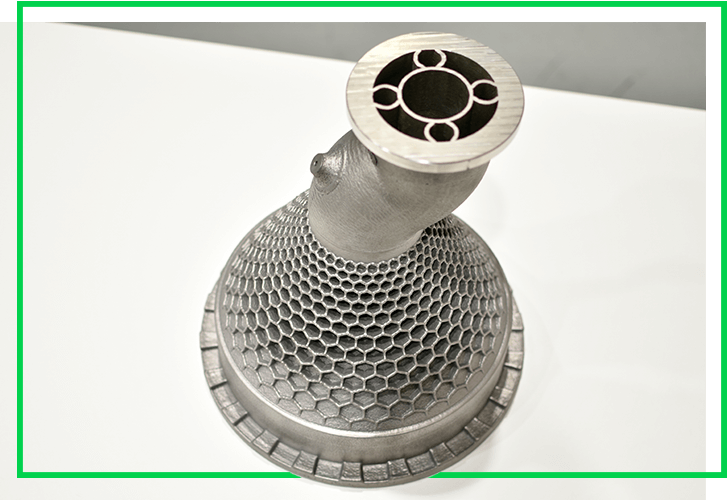

Evolution of Hot Isostatic Compaction to improve the surface finish of additive manufacturing parts

In keeping with our research and innovation efforts within the field metal additive manufacturing technologies, the IRT Saint Exupéry has upgraded its platforms and services by equipping its Hot Isostatic Pressing (HIP) machine with a gas analyzer.

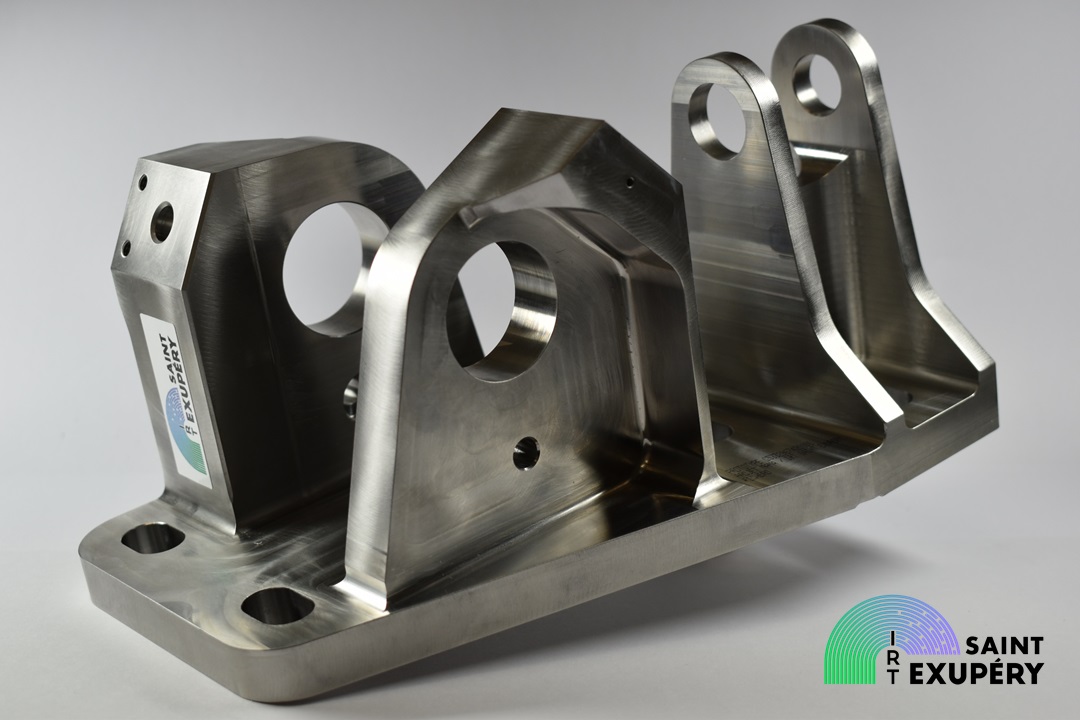

A 2nd key result on MAMA project: The manufacturing of a bracket for the Airbus Beluga

In the scope of the MAMA research project, IRT Saint Exupéry and RECAERO companies respectively located in Toulouse and Pamiers (France) tackled such challenges through the manufacturing of a bracket for the Airbus’s “Beluga” super-transporter (A300-600ST).

MAMA project: 30% raw material savings for titanium aerostructure parts

On April 21st, 2022, IRT Saint Exupéry held a press conference on the MAMA project (Metallic Advanced Materials for Aeronautics). During this occasion, IRT Saint Exupéry and the members of the project had the occasion to share and discuss about the technological and scientific advances of a project that will contribute to the reinforcement and[…]

ANDDURO project results: from the demonstration part to the critical one.

Since 2016, the IRT Saint Exupéry has been working in close collaboration with 15 industrial members and 4 academic members on establishing links between mechanical performance, microstructures, and parameters of metal additive manufacturing processes, with a view to their wider industrial use in the aeronautics and space sectors. The research work carried out within the[…]

METEOR Project: a technological breakthrough in the production of high-performance thermoplastic prepregs and composites.

After 3 years of research and tests, the scientific team of the IRT Saint Exupéry and the members of the METEOR project (coMpEtitive ThErmOplastic pRepreg) have completed a project that plays a very important role in the optimization of prepregs based on high-performance thermoplastics carbon fibers and resin. THE PROJECT METEOR’s mission was to develop[…]

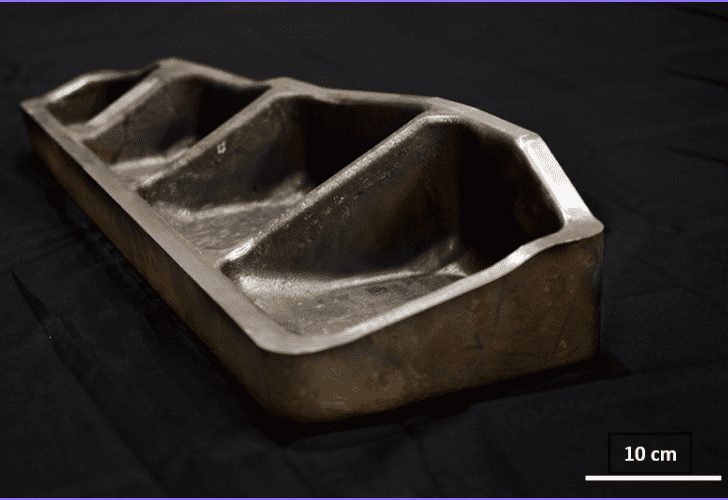

LMD-powder process: the DePÔz project has reached a new level of technological maturity through the design and manufacture of a unique demonstrator in record time.

The DePÔz demonstrator illustrates the growing maturity of the LMD-p process through the development of design and manufacturing rules, making the IRT Saint Exupéry a major player in the industrialisation of this technology. Laser Metal Deposition is a promising metal additive manufacturing technology for industrial applications. Indeed, the ability to adapt manufacturing parameters according to[…]

Congrats to Cassiopée Galy winner of the 2020 PhD Thesis Award from 3AF!

Cassiopée Galy, Research Engineer Additive Manufacturing at IRT Saint Exupéry won 2020 PhD Thesis Award from 3AF, the French scientific society of aeronautic and Space. Her thesis was supervised by I2M Laboratory and SPI Doctorale School of Bordeaux. THESIS SUBJECT Study of the material / process interaction in order to optimize the operating conditions of the SLM additive manufacturing process applied to[…]

A look back at one of the activities of the IRT’s composites division: thermoplastic composites.

These organic matrix composites, 50% lighter than steel, with exceptional intrinsic properties such as good damage tolerance, more resistant to temperature, abrasion due to corrosive products and high pressures and with good recyclability have been seducing industry for several years. These materials can be applied to numerous forming processes with shorter or more economical cycles[…]

GIFAS Thermoplastic Plenary Meeting @IRT Saint Exupery

The last GIFAS “Thermoplastics” annual general meeting was held this year at the IRT Saint Exupéry on June 6, 2019. Once again this major event for the French signatories allowed them to exchange views about current events in this sector and the various research projects carried out within the IRTs. The first day started with two[…]