he GIPSE project (Green Innovative Processes for Surface Engineering) is a direct continuation of the COBRA project (Control Of Bonding for Reliable Assemblies), led by IRT Saint Exupéry and its industrial partners.

While COBRA enabled a major step forward in mastering and industrializing advanced bonding processes, GIPSE now aims to extend these technologies to new materials, applications, and processes, while further strengthening robustness, understanding of underlying phenomena, and industrial scalability.

Looking Back at the COBRA Project: Mastering Adhesive Bonding Processes

The ambition of the COBRA project was to determine the critical parameters of adhesive bonding technologies in order to improve:

- Process robustness

- Performance

- Cost control

Industrial and academic partners : ARIANEGROUP, SAFRAN, Thales Alenia Space, Naval Group, Airbus, ICMCB and I2M joined this 39-month project.

Major Achievements

The work carried out led to significant advances, with a total of 21 deliverables:

• Laser Surface Structuring Before Bonding (Metals & Composites)

Identification of optimal operating parameters, integration of industrial constraints, and definition of process tolerances.

• Understanding Adhesion Mechanisms

In-depth analysis of laser–material interactions and mechanisms influencing assembly performance.

• Contamination Assessment and NDT Methods

Evaluation of the impact of industrial contaminants and inspection technique detection limits, along with the development of in-line monitoring solutions.

• Process Automation

Mastery of robotic laser treatment and integration of NDT techniques for in-line use, paving the way for more reproducible and industrially scalable processes.

The COBRA project laid solid foundations for the maturation of innovative bonding technologies through demonstrations carried out on representative technological samples, in close collaboration with major industrial partners.

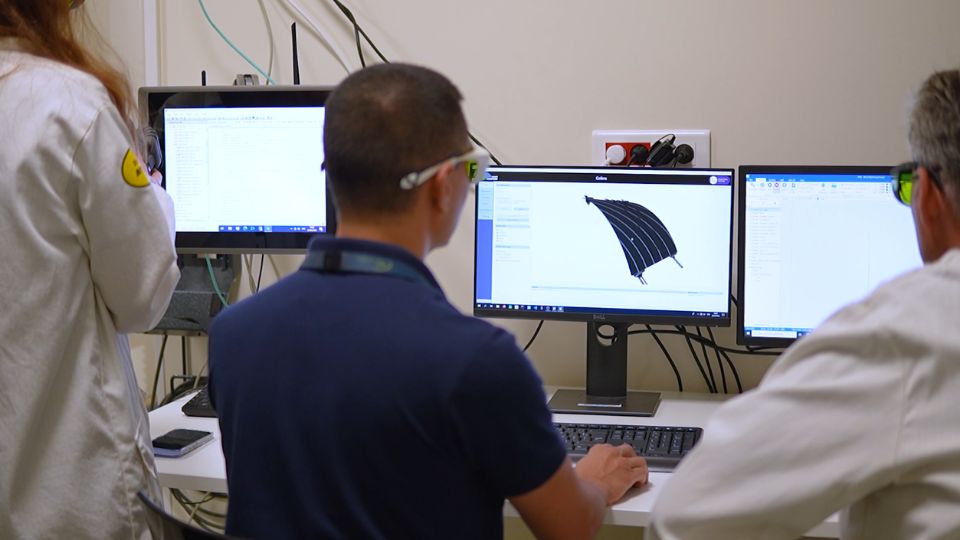

Within this framework, IRT Saint Exupéry relied on the synchronization expertise of IRT Jules Verne to develop a semi-autonomous laser process demonstrator. This system enables defect visualization and identification, as well as targeted process feedback on affected areas, ensuring part conformity at process output in direct response to industrial challenges.

GIPSE: Industrializing New Surface Preparation Processes

Building on these results, the GIPSE project together with its partners ARIANEGROUP, SAFRAN and Airbus aims to go further in mastering surface preparation technologies by broadening the scope of applications and materials studied.

Main Objectives of GIPSE

- Identify critical parameters of surface preparation technologies (prior to bonding, passivation, or chemical conversion).

- Improve process robustness and performance.

- Control costs and facilitate industrial integration.

- Ensure industrial transfer by anticipating automation and scale-up challenges.

While COBRA focused specifically on bonding applications, GIPSE explores a broader range of uses:

- Surface preparation prior to chemical conversion (IR nanosecond laser)

- Passivation (IR nanosecond laser)

- Surface preparation across a wide range of materials: aluminum, titanium, stainless steel, composites, painted surfaces, PTFE (IR & UV nanosecond lasers, atmospheric plasma precursor deposition)

Thanks to COBRA, IRT Saint Exupéry and its partners confirmed the relevance of laser and plasma surface preparation for improving the reliability of assemblies and surface treatments.

With GIPSE, this momentum is strengthened:

- More materials

- More industrial applications

- Greater scientific understanding

- A clear objective of industrial transfer

GIPSE therefore represents a strategic step toward safer, more robust, and more sustainable surface treatment processes, serving the aerospace and space industries.