The SOLER project (SO lders Lifetime Evaluation for Elec Ronics) was completed in August 2025 after three and a half years of research. Following the FELINE project, SOLER continues the transition toward more environmentally responsible technologies by addressing one of the major challenges in electronics: replacing traditional lead-based solder alloys with reliable lead-free alternatives.

A Core Objective: Ensuring the Reliability of Lead-Free Assemblies

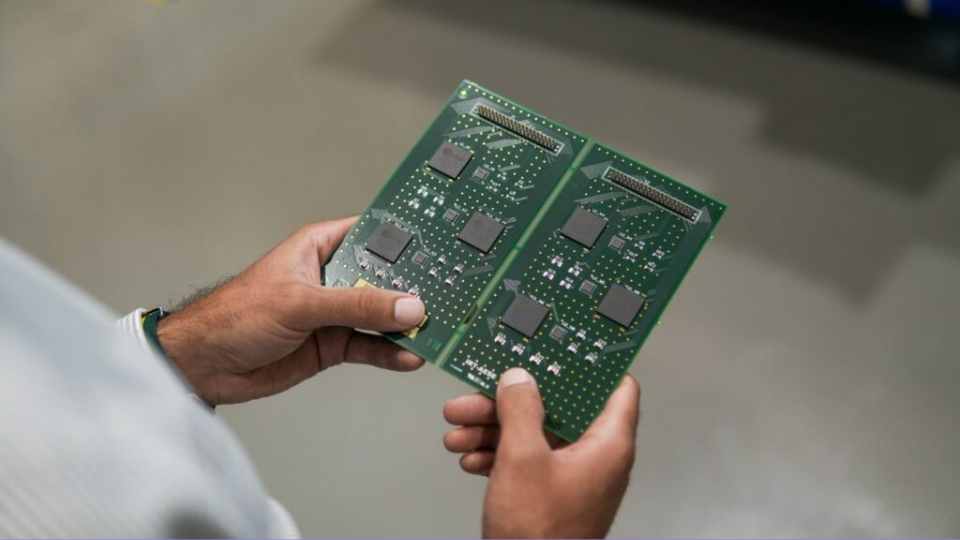

While FELINE focused on first-generation lead-free alloys (notably SAC305) and demonstrated both their strengths and limitations, SOLER aimed to evaluate the lifetime of electronic component assemblies mounted on printed circuit boards (PCBs) using next-generation lead-free solder pastes, particularly SAC+ (enhanced tin-silver-copper alloys) and LTS (Low Temperature Solder).

The goal was to assess their ability to replace earlier alloys while maintaining the high reliability required in the aerospace and space industries.

With a total budget of €1.4 million, the project brought together numerous industrial and academic partners, including Thales Alenia Space, Airbus, Elemca, Inventec, and IMS Bordeaux, with participation from CNES and DGA.

Four Scientific and Technical Objectives

- Compatibility and Reliability of Low-Temperature Assemblies

Replacing lead with traditional SAC alloys increases the reflow temperature by approximately 34°C, risking damage to electronic boards. Low-temperature (LTS) alloys offer a promising solution but remain poorly documented. The study aims to determine their robustness in limiting deformations and thermal stresses on the assembly. - Reliability of SAC+ Alloys in Aeronautical Environments

Assemblies on aeronautical PCBs were tested with SAC+ solder paste to evaluate their durability. Numerical simulations complemented the experimental tests to identify the most mechanically stressed areas. - Reliability of SAC+ Alloys for Space Applications

Under extreme thermal cycling conditions (e.g., −10 °C to +100 °C), assemblies were tested using optimized profiles to maximize stresses, representative of the space environment. The objective was to ensure long-term performance through detailed material characterization. - Modeling the Elastoviscoplastic Behavior of SAC+ Alloys

To improve the reliability of finite element simulations and lifetime predictions, the project focused on understanding the complex mechanical behaviors of SAC+ alloys under thermal stress and aging — a field still scarcely explored in the scientific literature.

Significant Deliverables

The project was divided into several work packages (WPs):

WP1 – State of the Art and Specifications

Objective: Establish the technical foundation by reviewing existing knowledge and defining industrial needs. This WP provided the scientific base for the project, defining materials, testing conditions, and methods used in subsequent tasks.

WP2 – Compatibility and Reliability of Low-Temperature Assemblies for Aeronautics

Objective: Test low-temperature alloys to limit thermal stress during assembly.

This WP assessed whether low-melting-point alloys could preserve the integrity of sensitive aeronautical components (BGA, QFN, etc.) through post-reflow analysis and lifetime testing under thermal cycling, including detailed study of solder joint structures after aging.

WP3 – Reliability of SAC+ Alloys for Aeronautics

Objective: Test the reliability of new SAC+ alloys (e.g., Innolot, HTO) for aeronautical PCBs.

This WP verified whether SAC+ alloys could serve as alternatives to conventional alloys while ensuring the robustness required for aircraft applications, using thermal cycling tests and in-depth structural analysis of solder joints after aging.

WP4 – Reliability of SAC+ Alloys for Space Applications

Objective: Evaluate the behavior of SAC+ alloys under extreme space conditions (vacuum, temperature extremes, etc.), addressing the specific needs of partners such as CNES and Thales Alenia Space.

Research Achievements with Promising Results

A postdoctoral researcher contributed significantly to the project. By combining thermal cycling tests with numerical modeling (Anand model), the study compared the performance of two alloy generations: SAC305 and SAC+. The aim was to understand how and why these solders degrade, particularly for the new SAC+ alloys (modified with elements such as bismuth).

Conclusion: Bismuth-doped SAC+ alloys show superior fatigue resistance compared to SAC305, especially under severe thermal environments, validating the potential of enriched alloys for critical applications.

Next Steps

The continuation of SOLER is underway with SOLER 2, aimed at further investigating the reliability of electronic assemblies in critical environments, particularly for aeronautics and space applications. Scheduled for a 42-month duration with a budget of €1.8M, SOLER 2 will build on previous work. Its objectives include:

- Detailed description of failure modes

- Modeling parameters (Weibull, Anand, fatigue laws)

- Evaluation of low-melting-point alloy compatibility

- Specific study of rework processes

- Non-destructive monitoring methodologies integrating AI and high-frequency measurements

Building on SOLER’s results, SOLER 2 continues the ambitious pursuit of lead-free assembly reliability, with promising prospects for the next generation of embedded electronics.