2023 marks the end of the COMPINNOV TP2 project. Three years of research and development into high-performance thermoplastic composite semi-finished products, giving us a better understanding of the links between prepregs materials and manufacturing processes.

Context

The IRT Saint Exupéry COMPINNOV TP2 project is part of the French aerospace industry, for aerostructure applications.

Most of these applications use metallic materials and thermoset composites. The French aerospace industry, which is constantly innovating, has for several years been interested in thermoplastic materials, which offer a number of advantages in terms of processability (weldability, increased production rates, etc.), re-processability, recyclability, performance (resistance to impact, aggressive fluids, etc.) and logistics (storage at ambient temperature, etc.).

It follows on from the COMPINNOV TP and METEOR projects, which focused on the development of materials and processes for high-performance unidirectional thermoplastic prepregs for consolidation out of autoclave.

The project

The aim of COMPINNOV TP2 was to demonstrate the potential for optimising the quality and performance of composite parts for different industrial processes, through the development of specific prepreg architectures.

In this field, the project activities were based on the IRT Saint Exupéry’s expertise in the development of tailor made prepregs and the knowledge of the industrial members (Airbus, Aviacomp, Hutchinson) on their production processes (AFP, welding, thermo-stamping, pullforming, etc.). Within the framework of the IRT Materials Alliance, the project also drew on the skills and resources of the IRT Jules Verne around its induction welding platform.

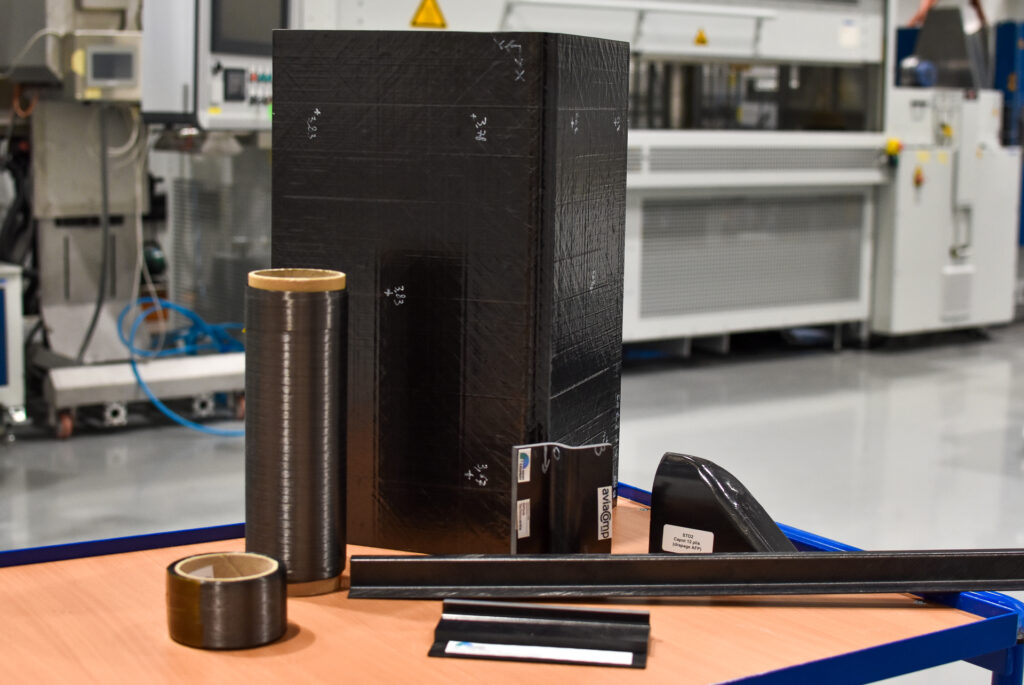

IRT Saint Exupéry 194gsm optimised architecture industrial technological samples made from C/PEKK prepregs

THE AIMS

- Developing a methodology for the development, characterisation and consolidation of high-performance thermoplastic prepregs

- Provide building blocks for understanding the relationship between materials and processing for various industrial processes used in the manufacture of aerostructures (stiffeners, cover, beams, etc.)

- Improve the capabilities (versatility, productivity, etc.) of the IRT Saint Exupéry’s thermoplastic prepreg development line.

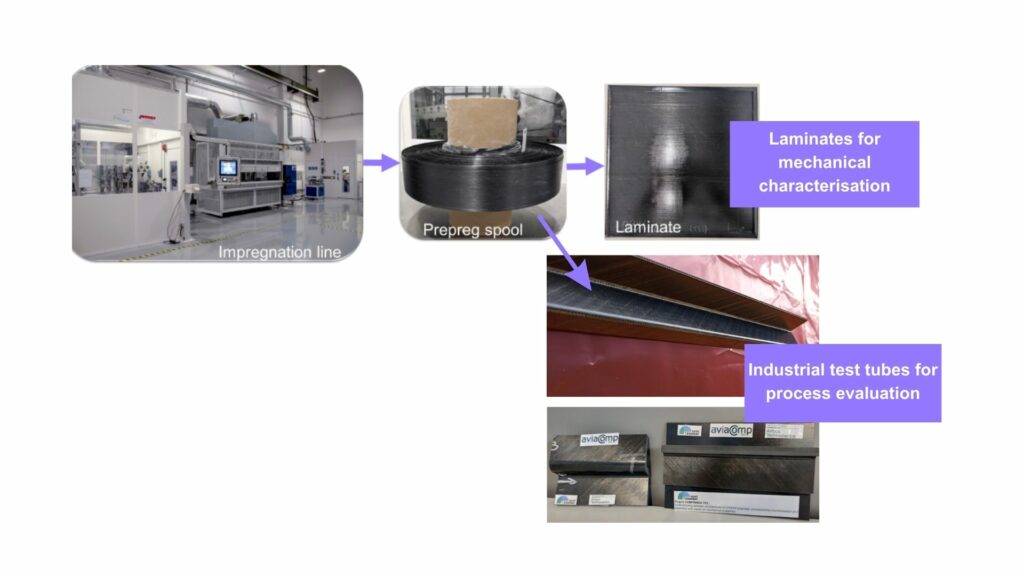

Production sequence and characterisation of prepregs

Compinnov TP2 (budget €1.4m) brought together a team of around ten people from the IRT Saint Exupéry alongside key partners Airbus, Aviacomp, Hutchinson and the IRT Jules Verne.

WHAT’S NEXT ?

IRT Saint Exupéry’s skills and resources in thermoplastic materials will once again be deployed in the INTREPID project, which aims to improve understanding of material/process interactions in the context of hybridisation between in-situ* AFP thermoplastic processes and additive manufacturing.

An impregnation line at IRT Saint Exupéry

The impregnation line at IRT Saint Exupéry supports studies on the development of new thermoplastic prepregs:

- Materials: increasing maturity, evaluation of innovative fibre/matrix combinations, development of new recycled, bio-sourced and functionalised materials, etc.

- Processes: evaluating/developing impregnation, process and quality control technologies, etc.

“The development of a methodology for developing, characterising and consolidating thermoplastic prepregs out of autoclave** has enabled us to gain a better understanding of the interactions between semi-finished products and processing methods. This support, coupled with our prepreg functionalisation capabilities, can be offered to any manufacturer wishing to improve the added value of its finished products based on a given fibre/matrix combination and processing method. The overall aim is to promote the use of thermoplastic materials in the French aerospace industry”, concludes Grégory ERB, COMPINNOV TP2 project manager.

*Automated lay-up without post-consolidation

** Oven consolidation