IRT Saint Exupéry pursues a series of portraits devoted to the men and women who best represent the institute: its researchers. Their high-level skills and wealth of experience contribute hugely to IRT Saint Exupéry’s performance and unique position, which is so crucial for its members and partners.

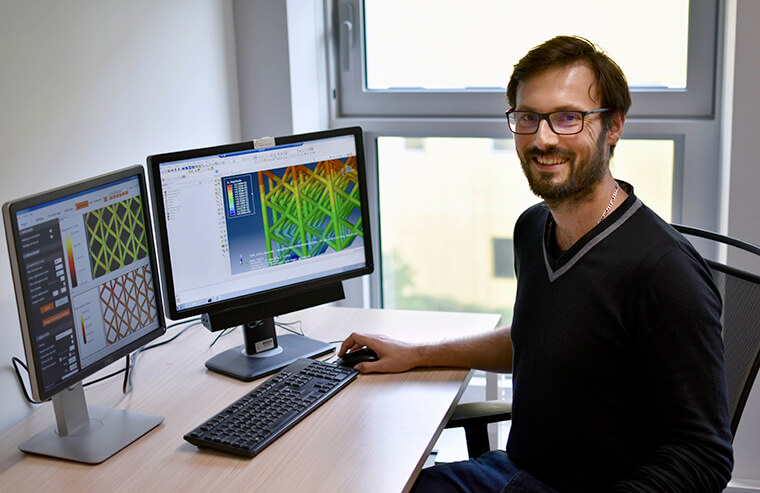

Ludovic Barrière, 32 years old, is an aeronautical research engineer specializing in structures, computational mechanics and numerical methods. Working at the intersection of these three skills, Ludovic is developing simulation models that aims at replacing the thousands of tests currently needed to certify aeronautical structures.

Can you tell us about your career so far?

I’m a graduate of a general engineering school[1] with a specialization in structures, computational mechanics and numerical methods, because I like to understand the techniques that are used to solve physical problems. After my internship on designing aircraft structures at Korea Air in South Korea, I knew I wanted to go down the path of research so I could avoid the repetitive side of the business. I decided to do a thesis[2] on aeronautics funded by EADS Innovation Works (formerly the Airbus Group) at the Clément Ader Institute[3], an environment that offered great opportunities in aircraft mechanical structures. Afterwards I worked for almost a year with simulation specialists at Cenaero, a private research center in Belgium that’s like the IRT model.

I came back to Toulouse in 2014, when I joined the COMPINNOV TD project in the materials field at IRT Saint Exupéry, looking at bird strikes using my skills in mechanics.

I discovered the experimental dimension while at the Clément Ader Institute, which has been developing research work and gas guns for several years. I was fascinated by the links between the experimental side and simulation and working on digital image correlation techniques.

Today, I’m applying my expertise to two IRT Saint Exupéry projects in parallel. The LASER project, which I’m in charge of, focuses on metal additive manufacturing. It’s about manufacturing and experimentally characterizing structures known as lattices – which have huge potential in terms of being streamlined and their performance – on different scales while developing predictive numerical models. The other project, VITAL, concerns composite materials. The aim is to develop and validate methods to replace the thousands of tests conducted in industry on test coupons – definition – as needed for certifying aeronautical structures.

Can you tell us more about the VITAL project that is starting up?

Can we trust simulation results to replace tests? There hasn’t yet been a large-scale answer to this question, which has been asked for a very long time by the aeronautical industry with virtual testing. In fact, the processes for designing an aircraft need to be modified; even today, it is based massively on tests. For Airbus, increasing simulation and reducing the number of tests is key. The company approached IRT, which positions itself here as a model integrator.Although our university partners are excellent at developing models, how can we ensure their reliability levels? With the implementation of validation strategies, we act as a bridge with the requirements of industry. The academic models are then exploited to the full and can be continuously improved by factoring in new cases.

VITAL Project (2019-2021)

- Industry members: Airbus, Stelia Aerospace

- Academic members: ONERA, University of Porto (Portugal), University of Girona (Spain)

LASER Project (2018-2020 )

- Industry members: Safran, Ariane Group, Altran, Thales Alenia Space

- Academic members: SIMAP [4]

COMPINNOVTD Project (2014-2018)

- STIMPACT Platform

We work in this area with IRT’s multi-disciplinary optimization experts, namely François Gallard and Matthias De Lozzo, because our work uses their GEMS software to manage the uncertainties of the materials’ properties, which are never exactly the same. We are going to estimate the impact of these uncertainties on the performance of composite structures to ensure that each part meets the specifications, irrespective of the material, with a certain variability range.

What results have been obtained and are expected?

The STIMPACT platform that has been set up with ICA and Airbus is a great achievement for the COMPINNOVTD project. It has made it possible to test a number of energy-absorbing technologies to protect aircraft against bird strikes. Some have shown mass and costs savings compared to current solutions. The inauguration of STIMPACT has been an amazing media success.

The LASER project has already produced numerous results. We now have the means to carry out tests on lattice structures equipped with four, 12-million-pixel cameras that can monitor the test in real time and measure displacement fields so we can compare the results with the simulation results using digital image correlation.

As for the VITAL project that is starting, we are moving forward in defining and implementing the integration platform that will be used to test and validate the methodologies.

What do you like at IRT Saint Exupéry?

I like the diverse nature of my work: being proactive on projects, including when setting up LASER and VITAL, as well as developing tests and models and understanding the industrial constraints. I also like the fact that I learn a lot from contact with academics and conducting research projects. Most of all, I take pleasure in working with colleagues who are enthusiastic and highly skilled in their fields. It’s inspiring.

I was lucky enough to finish my PhD thesis in 2014 when the IRTs came on the scene. This model, which is like the one in Belgium, fitted in with my wholehearted desire to work as a research engineer.

Is there something you’d like to share with us?

I took over the supervision of Marion Broutelle’s PhD thesis on ceramic matrix composites, a subject that is geared towards testing and simulation. This young PhD student has since been hired at Cnes. As her supervisor, I am proud of her work and her integration into the world of work! One day, I found my office had been decorated with glitter and unicorns. There’s no doubt that Marion was behind it: was it a sign of thanks or sweet revenge?

PUBLICATION & RELEASES

Bearing damage identification in oxide/oxide ceramic matrix composite with a new test design. M. Broutelle, L. Barriere, A. Daidie, A. Chardonneau, F. Bouillon, F. Lachaud. In Composite Structures (submitted)

Multiscale experimental and numerical analysis of 3D-printed IN718 BCCZ lattice structures, L. Barrière, B. Filloux, M. Suard, S. Pérusin, J. D’add, P. Lhuissier. In Int.l Conf. on Simulation for Additive Manufacturing SIM-AM 2019, Pavia, Italy, 2019

Methodology for identification of impact behavior of materials: application to bird strike. L. Barrière, M. Bouquet, J.F. Ferrero, 3rd International Conference of Mechanics of Composite, MechComp3, Bologna, Italy, 2017

STIMPACT Platform Inauguration (2017)

Surrogate model based mechanical characterization of lead-free soldered joint material exhibiting ratcheting behavior: An advanced methodology. B. Dompierre, L. Barrière, A. François, E. Wyart. In 16th Int. Conf. on Thermal, Mechanical and Multi-Physics Simulation and Experiments in Microelectronics and Microsystems, Budapest, 2015, pp. 1-5.

An adaptive model reduction strategy for post-buckling analysis of stiffened structures. L. Barrière, S. Marguet, B. Castanié, P. Cresta, J.C. Passieux. In Thin-Walled Structures, vol. 73, 2013, pp 81-93.

3D Digital Image Correlation Applied to Birdstrike Tests. L. Barrière, O. Cherrier, JC Passieux, M. Bouquet, JF. Ferrero. In Sutton M., Reu P. (eds) International Digital Imaging Correlation Society, Conference Proceedings of the Society for Experimental Mechanics Series, 2017.

[1] Ecole Nationale Supérieure des Mines de Saint-Etienne.

[2] Institut National des Sciences Appliquées de Toulouse (2013) – Subject: supercomputing strategies for the local post-buckling of large stiffened structures.

[3] ICA (CNRS/Mines Albi/INSA Toulouse/ISAE-SUPAERO/Univ. Toulouse 3 Paul Sabatier).

[4] Science et Ingénierie des Matériaux et Procédés (CNRS/Grenoble INP/Univ. Grenoble Alpes)